- TOP

- Sustainability

- SDGs Initiatives

SDGs Initiatives

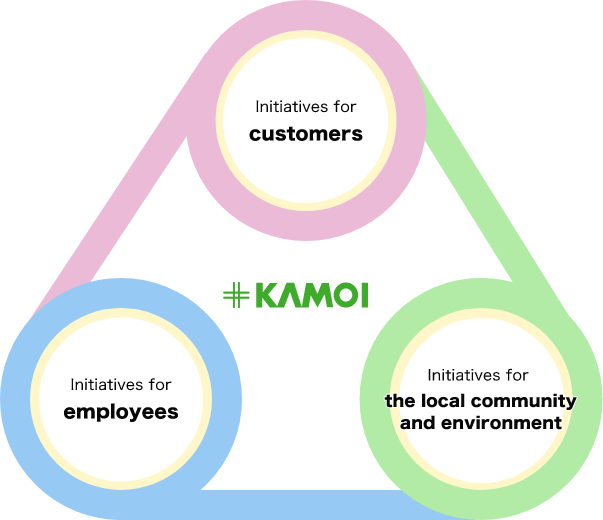

KAMOI KAKOSHI CO.,LTD. is committed to addressing three themes in line with SDGs (Sustainable Development Goals), as outlined below.

Initiatives for

customers

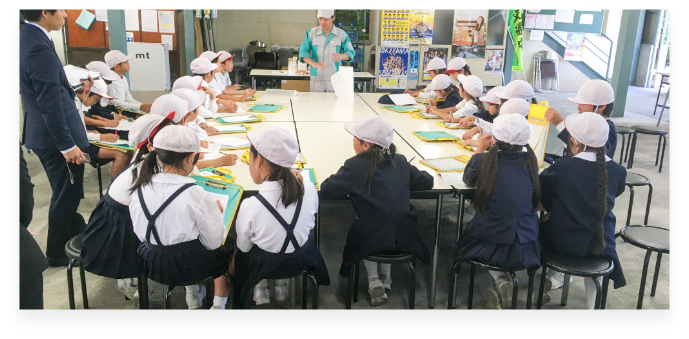

Factory tours for neighbouring elementary school students (as part of their social studies curriculum) and internships for junior high school students, high school students, and university students are actively conducted.

Factory tour events and various exhibitions are conducted.

Initiatives for

employees

Preparation for emergencies through evacuation drills and commitment to safety is undertaken.

Qualification of Hazardous Materials Engineer is recommended to obtain and commitment to safety is being undertaken.

As a measure against heat attacks in the summer, hydration is encouraged by providing complimentary water.

Certified as KENKO Investment for Health in 2024.

Initiatives for

the local community

and environment

Cleanup activities are undertaken in the Kurashiki Bikan Historical Area, Sami Coast, and the Kojima Lake Basin.

Solar panels are installed on the roof of the Yakage factory to focus on reducing the use of fossil fuel and greenhouse gas emissions.

We have obtained Forest Stewardship Council® (FSC®) / Chain of Custody (COC) certification (FSC®-C148008).

The Forest Stewardship Council®(FSC®)is an international nongovernmental organization that promotes environmentally appropriate, socially beneficial, and economically viable management of the world’s forest.

FSC®-C148008

To learn more, visit

ISO 14001 acquired and is implemented.

※ISO 14001 is the internationally recognized standard for environmental management systems.

Learn More (Move to the Japanese page.)

(Move to the Japanese page.)

We work with our suppliers to ensure that our procurement is socially and environmentally responsible.

Engaging the substitution of plastic tape with paper tape as part of efforts to reduce plastic usage.

Efforts are made to streamline lightweight packaging and packaging materials, as part of our commitment to be environmentally responsible.

(This initiative is jointly undertaken by the Sales Department and the Materials Department.)

Utilizing the "mt" heta box of our next 100 projects.

(Selling mt heta box in the online store.)

By changing the forklifts used in our factory to battery-powered, CO2 emissions are curbed.

The waste from tape and base paper are solidified into fuel, and waste from adhesive and oil are also converted into fuel, as part of our efforts towards thermal recycling.

Efforts are made to recycle waste cardboard and paper cores.

Efforts are made to reduce CO2 emissions and ensure an energy supply during disasters by transitioning the fuel for steam boilers from heavy oil to LPG.